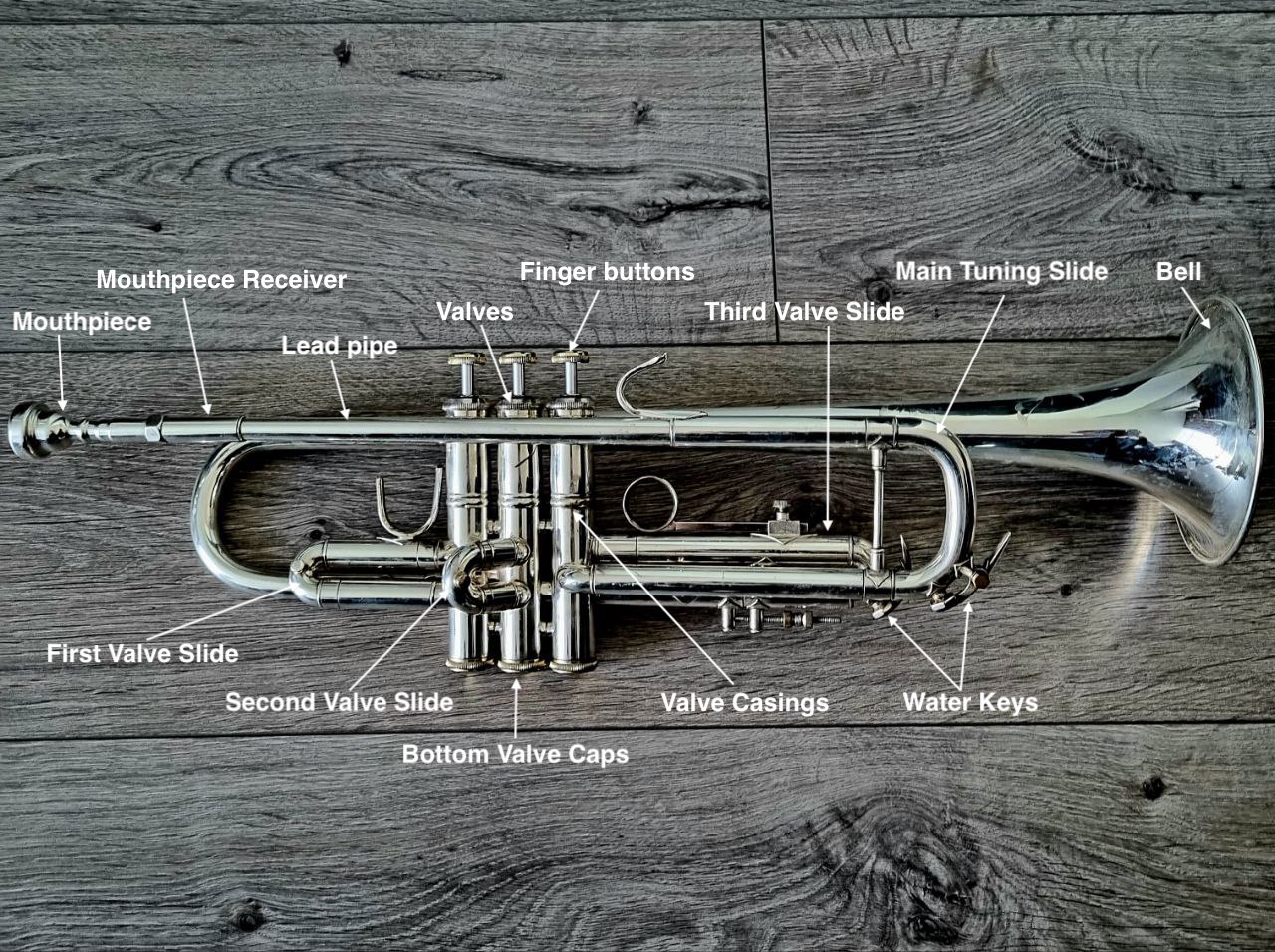

Complete Guide to Trumpet Parts - Anatomy & Functions of Bb Trumpet Components

Learn all trumpet parts with detailed diagrams and explanations. Comprehensive guide to mouthpiece, valves, slides, bell, and all Bb trumpet components for students and players.

Complete Guide to Trumpet Parts: Anatomy & Functions of Every Component

Whether you're a beginner trumpet player, music student, or teacher, understanding the parts of a trumpet is essential for proper playing technique, maintenance, and musical development. In this comprehensive guide, we'll explore every component of the Bb trumpet, from the mouthpiece to the bell, explaining their functions and importance in trumpet performance.

Understanding Bb Trumpet Anatomy - Complete Parts Overview

The Bb trumpet consists of several key components that work together to produce beautiful musical sounds. Each part serves a specific function in the instrument's operation, and understanding these components will help you become a better trumpet player and maintain your instrument properly.

Trumpet Mouthpiece: The Sound Source

The trumpet mouthpiece is where sound production begins, making it one of the most crucial trumpet parts for tone quality and playability. Every trumpet player must understand mouthpiece anatomy to achieve optimal performance.

Mouthpiece Components and Functions

Cup: The deepest part of the mouthpiece where your lips vibrate. Cup size and depth directly affect:

- Sound volume and projection

- Tone quality and timbre

- Playing range (high and low notes)

- Endurance during long practice sessions

Throat: The narrow opening connecting the cup to the backbore, controlling airflow resistance and response.

Backbore: The tapered section leading to the trumpet's lead pipe, affecting sound projection and intonation.

Choosing the Right Trumpet Mouthpiece

Bb trumpet mouthpieces are typically made of brass or silver-plated brass. Common mouthpiece sizes include:

- 7C: Standard beginner size offering balanced tone and comfort

- 3C: Medium-large cup for fuller sound

- 1.5C: Large cup for advanced players seeking rich, dark tone

Mouthpiece selection significantly impacts sound projection, endurance, flexibility, and ease of playing across different registers. Trumpet players often experiment with various mouthpieces to find their ideal match for specific musical styles and performance requirements.

Mouthpiece Receiver: Connecting Sound to Instrument

The mouthpiece receiver is a critical trumpet component located at the lead pipe where the mouthpiece is inserted and secured. This precision-engineered part ensures proper mouthpiece fit and optimal sound transmission throughout the instrument.

Function and Importance

The mouthpiece receiver serves as the initial point where sound vibrations from your lips are transmitted into the trumpet's tubing system. Key functions include:

- Secure Mouthpiece Connection: Holds the mouthpiece firmly while allowing easy insertion and removal

- Sound Transmission: Transfers lip vibrations efficiently into the trumpet's acoustic system

- Tuning Stability: Ensures consistent mouthpiece positioning for reliable intonation

- Airflow Direction: Channels player's breath into the trumpet's valve system

The receiver's design directly affects airflow resistance, sound resonance, and overall tone quality. A well-fitted mouthpiece receiver contributes significantly to the trumpet's responsiveness and projection capabilities.

Lead Pipe: The Airflow Highway

The trumpet lead pipe is a fundamental component that connects the mouthpiece receiver to the main valve assembly. This curved brass tube plays a vital role in sound production and instrument response.

Lead Pipe Functions in Sound Production

Airflow Direction: The lead pipe provides a clear pathway for air blown through the mouthpiece to enter the trumpet's valve system and continue through the main tuning slide.

Sound Shaping: Lead pipe design and dimensions significantly affect:

- Instrument resistance and response

- Overall timbre and tone color

- Sound projection and resonance

- Playing comfort and ease

Design Variations: Different lead pipe configurations can result in varying sound characteristics, from bright and focused to warm and resonant tones. Professional trumpet models often feature specialized lead pipe designs optimized for specific musical styles.

The lead pipe's curve and internal bore size influence how quickly the trumpet responds to player input and how efficiently sound travels through the instrument's acoustic system.

Main Tuning Slide: Master Pitch Control

The main tuning slide is one of the most important trumpet parts for achieving proper intonation and pitch accuracy. This adjustable component allows trumpet players to fine-tune their instrument to match other musicians and maintain accurate pitch across all registers.

How the Main Tuning Slide Works

Located near the center of the trumpet, the main tuning slide consists of two cylindrical tubes that can be extended or retracted to change the overall length of the instrument's tubing.

Pitch Adjustment Methods:

- Push In (Shorter Tubing): Raises the overall pitch

- Pull Out (Longer Tubing): Lowers the overall pitch

Tuning Slide Usage for Different Situations

Temperature Changes: Cold temperatures make brass contract, requiring the slide to be pulled out slightly to maintain proper pitch.

Ensemble Playing: Allows adjustment to match the pitch of piano, other brass instruments, or woodwinds.

Altitude Effects: Higher altitudes may require tuning adjustments for optimal intonation.

Regular use and proper maintenance of the main tuning slide ensures your trumpet stays in tune and performs optimally in any musical setting.

Water Keys (Spit Valves): Essential Moisture Management

Water keys, commonly called spit valves, are small but essential trumpet parts that allow players to remove accumulated moisture and condensation during performance. These mechanisms are crucial for maintaining optimal trumpet function and sound quality.

Location and Construction

Water keys are typically located on:

- Main tuning slide: Primary drainage point

- Third valve slide: Secondary moisture collection area

Each water key consists of a small metal lever connected to a drainage tube extending from the trumpet's main tubing system.

Why Water Keys Are Essential

Moisture Accumulation: During playing, warm breath meeting the cool brass creates condensation that can:

- Cause valves to stick or become sluggish

- Create gurgling sounds and poor tone quality

- Lead to mechanical problems if not removed

Proper Usage Technique:

- Hold the trumpet securely with one hand

- Press the water key lever while gently blowing air through the instrument

- Allow accumulated moisture to drain completely

- Release the lever to reseal the valve

Maintenance Tips for Water Keys

- Keep water key mechanisms clean and debris-free

- Apply light lubrication periodically for smooth operation

- Check for proper sealing to prevent air leaks

- Empty condensation regularly during practice and performance

Regular use of water keys prevents performance issues and extends your trumpet's lifespan while ensuring optimal sound quality.

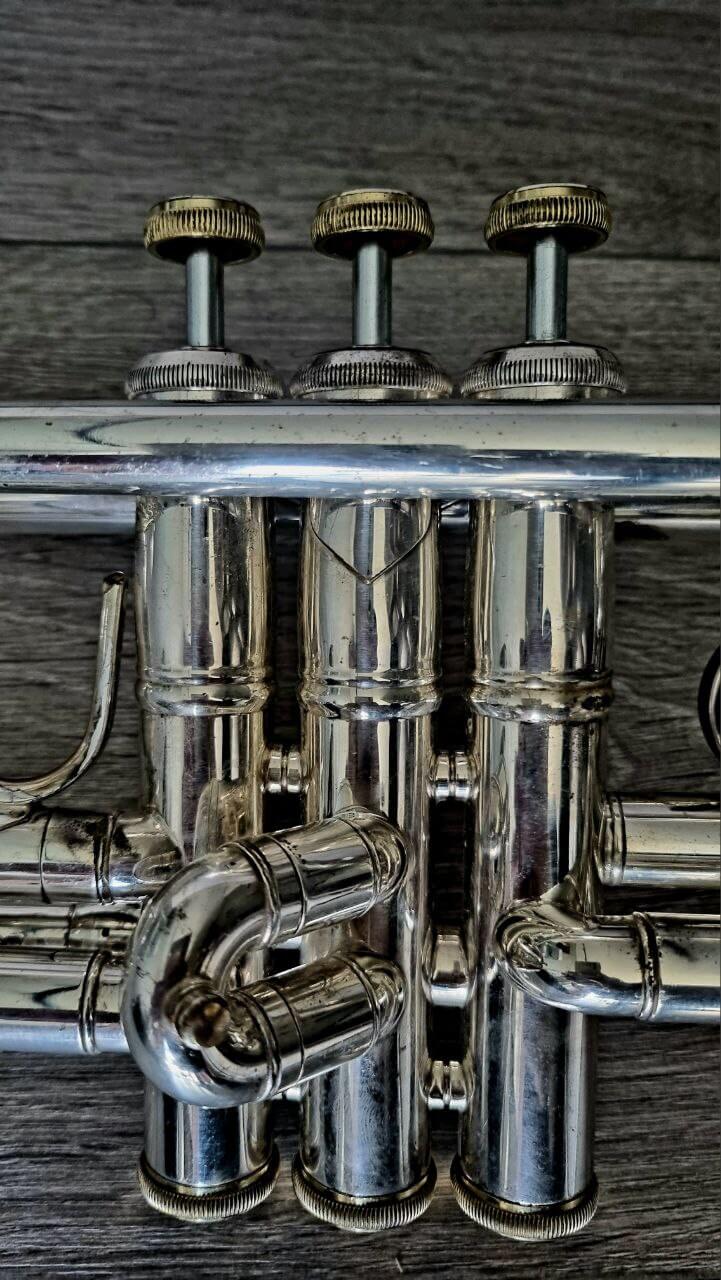

Trumpet Valves: The Heart of Pitch Control

The trumpet valve system is the most complex and important mechanism for controlling pitch and creating different notes. Understanding how valves work is essential for proper trumpet technique and maintenance.

How Trumpet Valves Function

Most trumpets feature three valves (first, second, and third) arranged linearly along the instrument. Each valve contains a piston that moves up and down within its casing to direct airflow through different tubing lengths.

Valve Positions:

- Up (Open): Air flows through additional tubing, lowering the pitch

- Down (Pressed): Air takes a shorter path, raising the pitch

Valve Combinations and Pitch Control

Individual Valve Functions:

- First Valve: Lowers pitch by one whole step (2 semitones)

- Second Valve: Lowers pitch by one half step (1 semitone)

- Third Valve: Lowers pitch by one and a half steps (3 semitones)

Combination Possibilities: By pressing different valve combinations, trumpet players can access a full chromatic range and play virtually any musical note within the instrument's range.

Valve Maintenance Requirements

Valve Oil: Regular application ensures smooth, responsive movement and prevents sticking.

Proper Alignment: Valves must fit snugly within casings to maintain airtight seals and prevent air leakage.

Regular Cleaning: Removes buildup that can cause sluggish valve action and poor response.

The precision engineering of trumpet valves allows players to execute rapid passages, smooth legato lines, and accurate intonation across the instrument's full range.

Valve Casings: Precision Housing for Trumpet Valves

Valve casings (also called valve cylinders) are the precision-engineered housings that contain and support the trumpet's piston valves. These critical trumpet components ensure smooth valve operation and maintain the airtight seals necessary for proper sound production.

Construction and Design

Material: Typically made of high-quality brass with precision machining for exact tolerances.

Configuration: Most trumpets feature three valve casings corresponding to the first, second, and third valves, arranged linearly along the instrument.

Internal Surface: Smooth, polished bore minimizes friction and allows valves to move freely and responsively.

Essential Functions

Structural Support: Provides secure housing and proper alignment for valve pistons during operation.

Airtight Sealing: Maintains pressure integrity throughout the trumpet's tubing system when valves are engaged.

Tubing Integration: Connects seamlessly with the trumpet's main tubing network to direct airflow through appropriate valve combinations.

Maintenance Considerations

Valve Oil Application: Regular lubrication of valve casings ensures smooth operation and prevents corrosion.

Precision Fit: Proper valve-to-casing tolerance prevents air leaks while allowing smooth movement.

Cleaning Requirements: Periodic cleaning removes buildup that could affect valve response and sealing.

Properly maintained valve casings are essential for optimal trumpet performance, enabling precise pitch control and responsive playing across all musical styles.

Finger Buttons: Ergonomic Valve Controls

Finger buttons (valve buttons) are the ergonomically designed controls that allow trumpet players to operate the valve system efficiently and comfortably. These small but crucial trumpet parts directly impact playing technique and performance capability.

Design and Function

Location: Positioned on top of each valve casing for optimal finger access and control.

Ergonomic Features:

- Rounded, contoured surfaces that fit finger shapes naturally

- Appropriate height for comfortable finger positioning

- Textured surfaces (ridges or knurling) for enhanced grip

Materials: Commonly made from brass, nickel silver, or modern synthetic materials for durability and comfort.

Importance for Trumpet Technique

Rapid Passages: Well-designed finger buttons enable quick, accurate valve combinations essential for technical passages.

Finger Independence: Proper button positioning allows each finger to move independently for complex fingering patterns.

Endurance: Comfortable button design reduces finger fatigue during extended playing sessions.

Customization Options

Many trumpet players customize their finger buttons for:

- Personal Comfort: Different shapes and sizes to match hand anatomy

- Aesthetic Preferences: Unique designs, colors, or engravings

- Performance Requirements: Specialized textures for enhanced grip in various playing conditions

Important Note: Any modifications should maintain valve functionality and not impede smooth operation.

Proper finger button maintenance includes regular cleaning to remove oils and debris that can affect grip and valve responsiveness.

Bottom Valve Caps: Securing the Valve System

Bottom valve caps (valve bottom caps) are threaded metal components that secure the lower ends of valve casings where valves connect to the trumpet's main tubing. These essential trumpet parts ensure proper valve seating and airtight system integrity.

Construction and Function

Materials: Typically made of brass or other durable metals matching the trumpet's finish.

Threading: Precision-threaded design ensures secure attachment and easy removal for maintenance.

Sealing: Creates airtight connection between valve casings and main tubing system.

Key Functions

Valve Security: Keeps valves properly positioned within their casings during playing and prevents valve displacement.

System Integrity: Maintains airtight seal essential for efficient airflow and proper sound production.

Maintenance Access: Removable design allows access to valves for cleaning, lubrication, and repair.

Maintenance and Care

Removal Process: Use proper valve casing wrench or trumpet maintenance tool to avoid damage.

Handling: Small size requires careful handling to prevent loss or misplacement.

Thread Care: Keep threads clean and lightly lubricated for smooth operation.

Replacement: Should be replaced if damaged or worn to maintain proper seal and valve function.

Regular inspection of bottom valve caps ensures optimal trumpet performance and prevents air leaks that could affect sound quality and valve response.

Trumpet Valve Slides: Fine-Tuning for Perfect Intonation

Valve slides (tuning slides) are adjustable trumpet components that allow players to make precise intonation adjustments for specific valve combinations. Each of the three valve slides corresponds to its respective valve and can be extended or retracted to achieve optimal pitch accuracy.

Why Valve Slides Are Essential

Intonation Correction: Compensates for natural pitch deviations that occur with certain valve combinations.

Temperature Adjustment: Allows pitch correction when temperature changes affect brass expansion and contraction.

Individual Note Tuning: Enables fine-tuning of specific notes that may be sharp or flat with standard valve positions.

General Valve Slide Operation

Extension (Pull Out): Lengthens tubing to lower pitch Retraction (Push In): Shortens tubing to raise pitch

Each valve slide requires different amounts of adjustment based on the acoustic properties of its associated valve combination.

Third Valve Slide: The Long Slide for Low Notes

The third valve slide is the longest of the three valve slides and plays a crucial role in achieving accurate intonation when using the third valve. This slide is particularly important for low register playing and complex valve combinations.

Physical Characteristics:

- Length: Longest slide on the trumpet

- Position: Extends from third valve casing toward the bell

- Operation: Manual adjustment during playing for real-time intonation correction

Musical Applications:

- Low Register Notes: Essential for proper tuning of notes using the third valve

- Multiple Valve Combinations: Critical when third valve is combined with first and/or second valves

- Advanced Techniques: Used in professional playing for micro-tonal adjustments

Playing Technique:

- Real-Time Adjustment: Many professional players adjust the third valve slide while playing to maintain perfect intonation

- Muscle Memory: Experienced players develop automatic slide positioning for common note patterns

- Listening Skills: Requires well-developed ear training to determine optimal slide positions

The third valve slide's length allows for significant pitch adjustment, making it an essential tool for advanced trumpet technique and professional-level intonation.

Second Valve Slide: Middle Length for Moderate Adjustments

The second valve slide occupies the middle position among the three valve slides in terms of both length and adjustment range. This slide is essential for fine-tuning notes that involve the second valve, which lowers pitch by one semitone.

Physical Properties:

- Length: Shorter than third valve slide, longer than first valve slide

- Position: Extends from second valve casing parallel to main tubing

- Adjustment Range: Moderate extension capability for precise tuning

Common Applications:

- Whole Step Combinations: When second valve is used alone or with other valves

- Chromatic Passages: Essential for accurate intonation in chromatic scales and passages

- Ensemble Playing: Helps match pitch with other instruments in band or orchestra settings

Tuning Considerations:

- Sharp Tendencies: Some second valve combinations tend to play sharp and require slide extension

- Temperature Sensitivity: Cold conditions may require additional slide adjustment

- Individual Instrument Variation: Each trumpet may require slightly different slide positions

Technical Usage: The second valve slide requires less frequent adjustment than the third valve slide but is still important for achieving professional-level intonation. Players develop sensitivity to when second valve slide adjustments are needed through practice and ear training.

First Valve Slide: Short Slide with Thumb Trigger

The first valve slide is the shortest of the three valve slides and often features a special ergonomic design for easy operation during performance. This slide is crucial for fine-tuning notes that use the first valve, which lowers pitch by one whole step (two semitones).

Design Features:

- Shortest Length: Requires the least extension among all valve slides

- Thumb Rest/Trigger: Many trumpets feature a U-shaped thumb rest for easy slide operation

- Quick Access: Positioned for rapid adjustment during playing

Operational Advantages:

- Left Thumb Control: The thumb rest allows the left thumb to extend the slide while maintaining proper trumpet hold

- Real-Time Adjustment: Can be adjusted during performance without interrupting playing technique

- Ergonomic Design: Reduces hand fatigue during extended playing sessions

Musical Applications:

- First Valve Notes: Essential for proper tuning when first valve is engaged

- Complex Combinations: Critical when first valve is combined with second and/or third valves

- Advanced Repertoire: Required for professional-level intonation in demanding musical passages

Maintenance Tips:

- Smooth Operation: Regular lubrication ensures easy slide movement

- Proper Alignment: Slide should move freely without binding or sticking

- Thumb Rest Care: Keep thumb rest clean and properly positioned

The first valve slide's unique design and frequent use make it one of the most important trumpet components for achieving accurate intonation and professional playing technique.

Trumpet Bell: The Sound Projector and Tone Shaper

The trumpet bell is the large, flared opening at the end of the instrument where sound exits and projects into the performance space. As one of the most visually prominent and acoustically important trumpet parts, the bell significantly influences tone quality, volume, and sound projection.

Bell Construction and Design

Materials: Typically made of high-quality brass, often with different alloy compositions for tonal variety.

Shape: Wide, flared cone that gradually expands from the narrow tubing to the large opening.

Size Variations: Bell diameter and flare rate vary among different trumpet models, affecting sound characteristics.

Acoustic Functions

Sound Amplification: Acts as an acoustic amplifier, increasing the volume and projection of sound waves produced by the player's lips and the instrument's resonance.

Tone Coloration: Influences the harmonic content and tonal color of the trumpet's sound:

- Larger Bells: Produce broader, more resonant sound with wider dynamic range

- Smaller Bells: Create focused, compact sound with enhanced projection

Resonance Enhancement: Functions as an acoustic resonator, reinforcing and shaping the vibrations from the trumpet's tubing system.

Bell Variations and Their Effects

Professional Models: Often feature specialized bell designs optimized for specific musical styles:

- Symphony Orchestras: Larger bells for rich, warm tone

- Jazz Performance: Medium bells for balanced projection and flexibility

- Commercial Music: Varied designs for versatile sound options

Maintenance and Care

Regular Cleaning: Remove fingerprints, moisture, and oxidation to maintain appearance and resonance.

Dent Prevention: Handle carefully to avoid damage that could affect sound quality and projection.

Protective Storage: Use proper cases and bell guards to prevent damage during transport.

Polishing: Regular polishing maintains the bell's appearance and can affect sound reflection properties.

The trumpet bell represents the final stage of sound production, where all the acoustic energy generated throughout the instrument is shaped and projected to create the distinctive trumpet sound that audiences hear.

Summary: Mastering Trumpet Parts Knowledge for Better Performance

Understanding every component of your Bb trumpet is essential for developing proper playing technique, maintaining your instrument, and achieving professional-level performance. Each trumpet part serves a specific function in the complex acoustic system that produces the trumpet's distinctive sound.

Key Takeaways for Trumpet Players

Sound Production Chain: From mouthpiece to bell, each component contributes to the trumpet's sound:

- Mouthpiece - Where sound begins with lip vibration

- Lead Pipe & Receiver - Direct airflow into the instrument

- Valve System - Controls pitch through tubing length changes

- Slides - Fine-tune intonation for perfect pitch

- Bell - Shapes and projects the final sound

Maintenance Priorities: Regular care of trumpet parts ensures optimal performance:

- Valve Oil - Keep valves moving smoothly

- Slide Lubrication - Maintain tuning slide responsiveness

- Water Key Operation - Remove moisture regularly

- Cleaning - Prevent buildup that affects sound quality

Performance Applications: Knowledge of trumpet anatomy enhances musical expression:

- Intonation Control - Use valve slides for perfect pitch

- Sound Modification - Understand how each part affects tone

- Technical Facility - Proper valve technique for complex passages

- Maintenance Skills - Keep your instrument in peak condition

Next Steps for Trumpet Development

For Beginners: Focus on understanding basic trumpet parts and their functions while developing fundamental playing skills.

For Intermediate Players: Learn to use valve slides effectively and develop sensitivity to intonation issues.

For Advanced Players: Master real-time slide adjustments and understand how equipment choices affect musical expression.

For Teachers: Use this trumpet parts knowledge to help students understand their instrument and develop proper maintenance habits.

Additional Resources

Continue your trumpet education with our comprehensive collection of resources:

- Interactive trumpet fingering chart for all notes and valve combinations

- Virtual trumpet simulator for silent practice

- Professional trumpet tuner for perfect pitch

- Complete trumpet scales guide for technical development

Understanding trumpet anatomy is the foundation for musical excellence. Whether you're just beginning your trumpet journey or seeking to deepen your knowledge, mastering these trumpet parts will enhance your playing, maintenance skills, and overall musical understanding.